One of the more infrequent but necessary jobs undertaken at a large observatory. A cross between heavy engineering (moving heavy weights around) and precision instrument work making sure that the mirrors go back to exactly the right position and that everything works correctly afterwards.

Usually this is done at the onset of winter. It generally takes 3 days to remove a mirror, strip off the old coating, re-aluminise it and re-fit the mirror and its cell back on the telescope. Although the re-coating process only takes a few hours (with most of that time being taken to produce the high vacuum in the aluminising tank) the mirror is left overnight in the tank for the new coating to harden. It is only a few microns thick and very delicate when fresh.

It was once common practice to re-aluminise the mirrors annually, but to keep the telescope downtime to a minimum, in recent years other methods have been adopted such as snow cleaning (with CO 2) or washing at regular intervals. The mirrors are only re-aluminised if the coating has deteriorated to the point where cleaning using the methods stated above are ineffective.

The 1 metre JKT mirror

Photos taken in 1987

Seen in the photo from L to R: Amado Guillen, Ken Maris, Andy Inchley, Vincente Reyes and Servando Rodriguez.

Ken Maris and Nick Ferneyhough making final checks before winching the mirror cell back into place

One of the three load cells which measure the compressive/tensive forces of the mirror can be seen in this photo. To the right of the load cell is one of the three radial position defining rods which prevents the mirror from twisting in the cell.The 2.5 metre INT mirror

Photos taken in 1986

These series of photos are quite historic as the aluminising tank shown (the original from the RGO at Herstmonceux) was decommissioned in the late 1980's and all aluminising operations since have been carried out using the aluminising plant in the WHT. From what I remember this tank took many hours to evacuate and the WHT equipment it is much quicker.

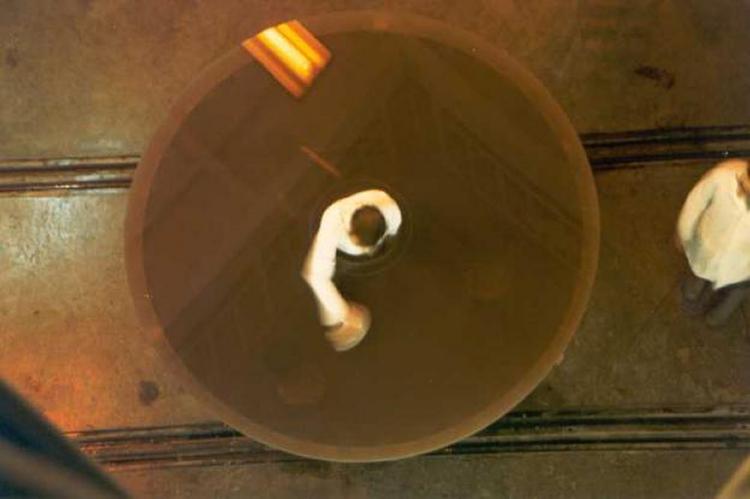

Another reason why large telescopes have a central hole in the primary mirror!

One of my favourite photos showing Roy Wallis drying off the mirror after its been washed with distilled water. The old aluminium coating was first removed using caustic soda. Its imperative that the mirror is perfectly clean and dry before it goes into the aluminising tank.

The brackets around the circumference of the mirror must line up perfectly with the radial defining arms mounted on the mirror cell.

The 4.2 metre WHT mirror

Photos taken around 1989

As the WHT is the largest of the ING telescopes, re-aluminising the mirror is a very impressive (and at times a stressful) operation. Before the mirror cell can be removed from the telescope, a large handling trolley is craned up to Cassegrain access platform, but first a section of the platform is removed to make enough clearance for the trolley (and the mirror) to be raised or lowered to the ground floor. The working space is very tight. The mirror weighs 16 and its cell 21 metric tonnes.

The aluminising process

When the mirror has been released from its cell, it is lowered to the ground floor and sits on three pedestals. The old aluminium coating is removed using caustic soda and the mirror hosed down. It is then given a final wash with distilled water and dried to ensure that no contaminents remain.

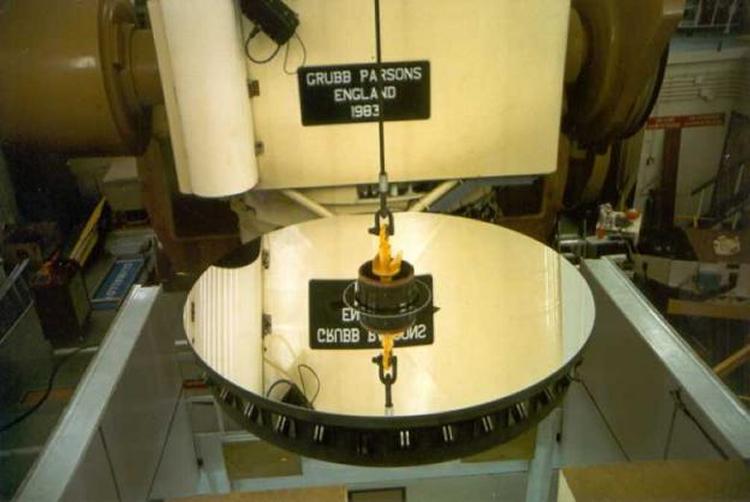

The WHT aluminising tank consists of two sections. The lower section holds the mirror and can move out on rail tracks into the drum of the building. The upper section is fixed but can be driven upwards to allow for tank separation. One of the first jobs is to prepare the upper section of the tank by placing pure aluminium wire loops on to a circular busbar. When the mirror is clean, it is craned into the lower section of the tank which is driven back into the aluminising area and the tank sealed. Powerful roughing pumps begin the evacuation process and when a certain level of vacuum pressure has been reached, turbo molecular pumps kick in to take the vacuum down to the required level. Other processes are also involved to remove any gas molecules still left in the tank. At the point when aluminisation will take place, a heavy current passes through the busbar and vaporises the aluminium onto the mirror. It is possible to see this process taking place through the 'porthole' shown in the photo below. A purple mist being seen. The whole process is automated and takes just a few hours.

As a point of interest, the WHT aluminising tank was at the time the widest load to be carried up the winding mountain road from the harbour in Santa Cruz to the observatory. Not the sort of thing that could be sent up in sections like dome or telescope parts that were assembled on site.

Dave and Ken carefully rotating the mirror so that it lines up correctly in the cell.

The counterbalanced radial defining arms can be clearly seen in this image. As the WHT is an alt-azimuth mounted telescope, these arms are only required at the axis of where the telescope moves in elevation. The INT (and JKT which uses a different arrangement) being equatorially mounted require radial definers equally spaced around the circumference of the mirror.

"Bring it down a bit more!"

Eddie Penny signalling to the crane operator up on the dome balcony. Also seen in this photo is Dave Benham to the left and Ken Maris with another guy (who I can't make out) at the rear.